Harvesting

Harvesting

(Courtesy of Canola Council of Canada)

Canola Swathing - Seed Color Change - Video

(Courtesy of Canola Council of Canada)

PS-2154 Harvesting Options for Winter Canola

Swathing vs. Direct Combing (pdf)

Tips to reduce wind damage to swaths

Why is desccated canola not drying down? (Reglone PDF file Harvest Aid)

Winter Canola Harvest

- Canola is an indeterminate crop and has a certain amount of immature seeds at harvest.

- Canola is ripe when the pods are dry and rattle when shaken.

- Seed is dark brown to black in color at maturity. Stems will still be partly green.

- Harvest at 8 to 10% moisture. Dryers? 11 to 13%.

- Canola should be cut just below seed pods.

- Straight combining will perform better in heavy canola where it is leaning, with pods "laced" together.

- Canola that is ready should be harvested immediately.

- Swathing is possible alternative for harvesting winter canola.

Harvesting Canola

- Proper Harvest Moisture: 9-10%, canola will store well at this moisture.

- Combine Settings: Follow manual for rapeseed (John Deere.com).

- Slow cylinder speed slow as possible (450-550RPM).

- Open concave 3/4 of the way. 1 to 1 1/2' clearance on concave settings.

- Fan speeds set at 2/3 of small grain settings (750-850RPM).

- Rotor Speed 350-650, Concave indicator 10-20, Fan Speed at 700 RPM

- Match reel speed with ground speed. Set fingers straight up and down to minimize wrapping.

- Proper speed: A slower speed will be needed compared to small grain.

- Duct Tape!!!!!!! Very Important .

Conventional Combine

- Cylinder speed should be slow. About 1/2 to 2/3 that for wheat. (450 - 650 rpm)

- Concave clearances - 3/4" in the front and 1/8 - 1/4' in the rear.

- Fan speed is similar to wheat (400 - 600 rpm).

- To sieve / chaffer set at 1/4 to 3/8" for proper separation and lower cleaning sieve set at 1/8 to 1/4".

Axial-Flow Combine (Case 2388)

- Rotor Speed - 500 RPM

- Gear Range - Middle

- Concave - Small wire setting #4

- Chaffer Setting - Front 1/4", Middle 1/2", Rear 1/2"

- Shoe Setting - 1/16" round hole

- Fan Speed - 600 RPM

- Grate Type - Slot

Rotary Combine

- Use preset settings from operators manual. Most can be setup from the cab by crop.

- Cylinder speed should be slow. About 1/2 to 2/3 that for wheat. (350 - 650 rpm.)

- Concave clearances - 3/4" in the front and 1/8 - 1/4 in the rear.

- Fan speed is similar to wheat (520 - 700 rpm).

- Chaffer clearance 3/8 to 5/16"

- Sieve Clearance 3.32 - 3/16".

Reduce Shatter Loass by Combining:

- A ripe crop at higher seed moisture levels and drying the seed.

- In the cooler part of the day.

- At night when pods are damp from dew.

- At night during periods of very hot weather.

- Average seed losses in the field can range from 0.2 to 1 Bu/A.

- Canola can be harvested when too damp to harvest wheat.

However, seed moisture levels must be continuously monitored to ensure they do not exceed safe storage levels.

Winter Canola - Swathing Setup

- It is critical that the plant be at the proper stage of maturity.

- Plants should be swathed when 60 to 75% of the seeds are black and contain 30 to 40% moisture.

- The swath is placed on stubble for approx. 7 to 10 days or until the seed moisture is 8 to 10%, when the crop should be combined.

- Research has shown a possible yield reduction of 10% can occur when swathed at the optimum stage compared to direct combining.

- Typically canola producers can swath and pick up canola before wheat is ready to harvest.

- Under moderate windy conditions there is less shatter loss when canola is in a windrow compared to ripe canola left standing.

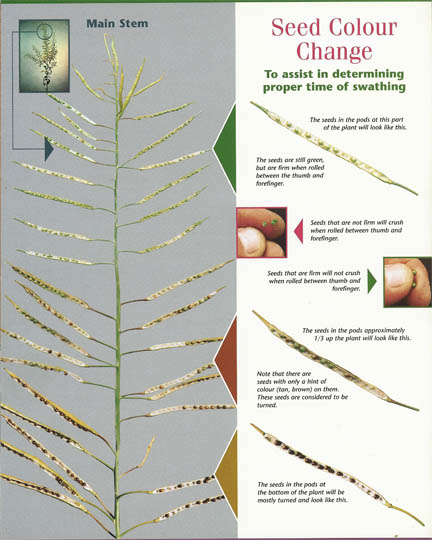

Winter Canola Harvest- Time of Swathing Guide

- Start inspecting field approximately 7 to 10 days after flowering ends.

- Walk out and sample 5 to 10 plants. Most of the seeds in the top pods will be firm, and roll, as opposed to break or crush, when pressed between the forefinger and thumb.

- Using the seed color change chart take note on the percentage of the plants. Examine only pods on the main stem. Seeds in pods on the bottom third of the main stem mature first. Only seeds with small patches of color (spotting) should be counted as color change.

- After assessing the main stem, look at the seed from the pods on the side branches to ensure that they are firm with no translucency, especially with low plant populations.

- Once sampled average out the percent seed color change for that filed.

- Continue inspections every 3 to 4 days to monitor color change in the first formed pods on the bottom of the main stem.

- Key to curing crop is moisture. The enzyme responsible for clearing the chlorophyll requires moisture. Curing will take approx. 14 days.

- Best time to swath is when all the seeds contain about 30 to 35% moisture. The color of the seed is a good indicator of seed moisture content.

- At the proper moisture about 30 to 40% of the seeds in the pods on the main stem will have changed color or have started to change color.

- When conditions are hot and dry, swathing is not recommended. Swathing during the cool evening hours, at night, or early morning will allow the plant to dry down at a slower rate. Lowering the chance of green seed and poor oil content.

Tips on Combining

- Combine table should be set low when first starting out.

- Leave reel positioned up and away from the table to prevent shattering

- As crop begins flowing into the combine, begin to raise the table and lower the reel.

- Don't use too much reel on the crop.

Combine Tips to Reduce Harvest Loss

- First, set your combine by the book

- Then you may need to:

- Slow down the cylinder

- Adjust the concaves

- Close the sieves

- Reduce the air

- Raise the reel

- Put reel directly over sickle

- Match Reel speed with ground speed

- Cut just below the pods

- Slow down at first, then see how much you can speed up

- Check for leakage on your trucks/combines

- Aim for 2.0% dockage or less

- Tarp your trucks

Pushing

Pushing is a relatively new procedure for canola harvesting that has been suggested as a faster and less expensive alternative to swathing. A pusher is mounted on the 3 point hitch of a bi-directional tractor and it is driven through the canola at a relatively high speed to force it to lodge. Mounting a pusher on front loader brackets has not been successful because the unit is too wide and too heavy and must be kept level during relatively high speed operation. The idea is that by pushing the canola over it is less susceptible to blowing in the wind, which causes shattering. Although our experience with pushing is very limited, it appears that it may work better in some crop situations than in others. Tall even crop growth works better with pushing. Shorter and thin crops simply stand back up, minus a few pods, after the pusher has gone over them. The optimum speed for pushing may vary depending on crop size and density. The idea is to push the stalks over, but not break them off or rip them out of the ground. Vertical sickles at both ends and directly in front of the tractor tire tracks are designed to insure a clean cut between passes and reduce the amount of canola crushed to the ground by the tire tracks. Pods cut off by these sickles are likely to be lost onto the ground. After the crop matures it is combined with a typical header. The combine must travel in the exact opposite direction of the pusher. The combine header also has to operate much closer to the ground than for standing canola. Combining is slower, because of the additional stalk material that enters the combine. Pushers may work best in fields with high production potential and few or no terraces. Growers should carefully scout their fields for armyworms and other foliage feeders and if they are present control them before pushing, or forcibly lodging their canola. A few growers in Oklahoma plan to try pushing their canola in 2009.